Name Jeff Leichliter

- Education Military Training, OJT

- Target Audience High School

Where there's a will, there's a way. Jeff Leichliter, Industrial Robotics Engineer, found his way to a rewarding STEM career without the help of a college degree. Jeff was able to translate his military electronics training into a career in the field of industrial robotics, and now he spends his days surrounded by giant pieces of industrial equipment. Read on to find out how Jeff's interdisciplinary skill set fosters his creativity in problem solving.

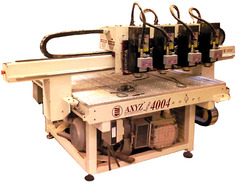

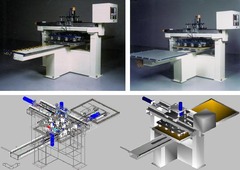

I am an automation specialist, which means that I design and build industrial robotic machinery. A customer will come to me with an item or part that needs to be manufactured and I build the machinery that will meet this end. I build the machinery from the ground up, including part design, welding and assembly, set-up, testing, wiring, and electrical, pneumatic, and electronic systems, PC configuration and programming of all systems and devices. I've worked on hydraulic systems and, in the past, I've owned CNC mills and a lathe to make my own parts. That's one of the fun parts of my job - I get to do it all. Most of the time, these projects have computer specialists, programmers, welders, machinists, electronics specialists, and pneumatic specialists. However, I get a do it all.

I am an automation specialist, which means that I design and build industrial robotic machinery. A customer will come to me with an item or part that needs to be manufactured and I build the machinery that will meet this end. I build the machinery from the ground up, including part design, welding and assembly, set-up, testing, wiring, and electrical, pneumatic, and electronic systems, PC configuration and programming of all systems and devices. I've worked on hydraulic systems and, in the past, I've owned CNC mills and a lathe to make my own parts. That's one of the fun parts of my job - I get to do it all. Most of the time, these projects have computer specialists, programmers, welders, machinists, electronics specialists, and pneumatic specialists. However, I get a do it all.

I completely fell into this career by accident. After high school, I went into the Air Force and was educated on navigation equipment. I didn't know what I wanted to do in the Air Force, but I did well on my testing, so I looked on the list and picked the track that provided the most education. My family couldn't afford college, so I really wanted to take advantage of the education offered by the service. There were two tracks that offered the most school - one was called flight facilities equipment repairman, or NavAids (navigational aids), and the other track was radar. I didn't choose to work on radar, because I would have been working in a control tower. I wanted to be more of a field guy. While working as a Flight Facilities Equipment Repairman, I got to work on antenna arrays and all the different electronics that help airplanes take off and land. If you ever fly somewhere and you look down when you are over the airport, you will notice orange and white checkered buildings. Those are the buildings I used to work on. They send out a signal in a 200 mile radius to help airplanes identify where they are as well as create an invisible funnel in the air that guides them in for a safe landing (very useful in bad weather and foggy conditions).

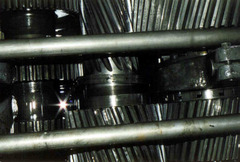

When I got out of the service, I still didn't know exactly what I wanted to do for living, so I jumped on foot and went looking for a job. I started out repairing copy machines and I quickly became good enough at that to be able to completely rebuild the machines. This type of work really fit in with my military electronics training. One day, I was in a machine tool dealer's office repairing their copy machine when I overheard the owner telling someone on the phone that he needed a good serviceman. While I fixed their machine, I waited for him to get off the phone. When he was done, I told him I was a good serviceman. He ended up hiring me and, within six months, I was retrofitting - or updating - all of the controls for their milling machines. Sometimes the machines were manual machines, so I had to dismantle them and install components, such as ball screws and servo motors, in order to automate them. Normally, with a manual machine, the operator is turning handles and reading dials in order to make it run. When I would retrofit a machine, I'd install motors in it in a fashion that allowed a computer to control the motors and make the ball screws turn. I worked there for three and half years and then decided to go out on my own, designing and building industrial robotic machinery.

When I got out of the service, I still didn't know exactly what I wanted to do for living, so I jumped on foot and went looking for a job. I started out repairing copy machines and I quickly became good enough at that to be able to completely rebuild the machines. This type of work really fit in with my military electronics training. One day, I was in a machine tool dealer's office repairing their copy machine when I overheard the owner telling someone on the phone that he needed a good serviceman. While I fixed their machine, I waited for him to get off the phone. When he was done, I told him I was a good serviceman. He ended up hiring me and, within six months, I was retrofitting - or updating - all of the controls for their milling machines. Sometimes the machines were manual machines, so I had to dismantle them and install components, such as ball screws and servo motors, in order to automate them. Normally, with a manual machine, the operator is turning handles and reading dials in order to make it run. When I would retrofit a machine, I'd install motors in it in a fashion that allowed a computer to control the motors and make the ball screws turn. I worked there for three and half years and then decided to go out on my own, designing and building industrial robotic machinery.

My military training translated very well because of the heavy electronics training. I learned the theory behind electronics and how they work, so when I started working with computer-based machines, it translated almost exactly to what I did in the military.

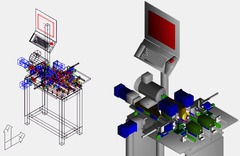

My average workday really varies. I spend some days at the computer designing a machine. I can spend months designing a machine, drawing all the motors, ballscrews, bearings, and assemblies, using a CAD (Computer-Aided Design) system. The program I use now is an AutoCAD-type system. It allows me to draw solid forms of the machine's components and assemble them together. By using this system, I'm able to see a solid model of what the machine will look like when it is finished. The drawing gives a 3-D picture and I can rotate it to look at the back and top of it. I typically draw down to increments of 1/10000th of an inch (.0001"), so I'm able to scale everything down as small as that. With the drawings, I can test the machine with the software to make sure there's no interference between any of the components. I also use the component drawings to draw the actual parts I will need to build the machine components. Then I give these drawings to the people who manufacture parts. They take pieces of metal or plastic and make the parts. Ironically, these parts are often made on machines that I built. When I'm done designing the machine, I build it from the ground up. It's like assembling a 3-D puzzle.

My average workday really varies. I spend some days at the computer designing a machine. I can spend months designing a machine, drawing all the motors, ballscrews, bearings, and assemblies, using a CAD (Computer-Aided Design) system. The program I use now is an AutoCAD-type system. It allows me to draw solid forms of the machine's components and assemble them together. By using this system, I'm able to see a solid model of what the machine will look like when it is finished. The drawing gives a 3-D picture and I can rotate it to look at the back and top of it. I typically draw down to increments of 1/10000th of an inch (.0001"), so I'm able to scale everything down as small as that. With the drawings, I can test the machine with the software to make sure there's no interference between any of the components. I also use the component drawings to draw the actual parts I will need to build the machine components. Then I give these drawings to the people who manufacture parts. They take pieces of metal or plastic and make the parts. Ironically, these parts are often made on machines that I built. When I'm done designing the machine, I build it from the ground up. It's like assembling a 3-D puzzle.

When I am not drawing or building a new machine, I service existing machines. To service a machine, I have to dig into manuals and learn about the machines, troubleshoot them, and fix whatever is wrong with them. I rarely get the same type of machines. This is one the fun parts of the job, because I have to continually learn about new machines. I love learning. Sometimes, the process gets a little sticky and takes longer than I would like, but there is always a learning curve with everything you do in life.

When I am not drawing or building a new machine, I service existing machines. To service a machine, I have to dig into manuals and learn about the machines, troubleshoot them, and fix whatever is wrong with them. I rarely get the same type of machines. This is one the fun parts of the job, because I have to continually learn about new machines. I love learning. Sometimes, the process gets a little sticky and takes longer than I would like, but there is always a learning curve with everything you do in life.

After I've spent a lot of time designing, assembling, and wiring and I'm done with all the work on a machine, the most rewarding experience is the first time I turn on the switch and the machine runs correctly. Sometimes this doesn't happen the first time. I might've overlooked or forgotten about something and I have to go back and make that particular component work or design the particular stage that I forgot about. This process is called debugging. Ultimately, the best part of my job is to see the machine running correctly and doing the job it is supposed to do. Then I get to shake hands with the owner of the machine and leave the shop. Although the customer is satisfied, for me the reward is walking away from that machine and hopefully never seeing it again. Ideally, the machine runs and doesn't break.

Another benefit of my career is that I've been able to conduct my job from my shop at home. That allowed me to be home with my kids. I would work before they got up, after they went to bed, and while they were at school.

I was good at a lot of things and I really didn't have a focus area. All I really tried to do was get good grades. My parents always drove me to get good grades, so I studied everything and took the time necessary to learn those subjects. I thought science was interesting and I thought history was boring. I was always good at math and that's a fundamental requirement for what I do. When I'm drawing, I have to be able to divide shapes and components in sections and add the numbers up.

The biggest challenge was having to learn everything by myself. I couldn't afford college and I wasn't sure what to do, so I grabbed a book and start reading. When I found my interests, I would spend a great deal of time studying what I needed to learn. These days, it gets a little difficult when half of what I read is in Japanese, Spanish, Italian, or some other language. When I service existing machines, a lot of them are made in Europe or Asia and the manuals are often in languages from those regions. However, one thing that is universal is electricity. Electricity is the flow of electrons and they flow like water going from one point to another or cars travelling from one town to another. Electrical schematics are like the road maps. The wire goes from one device to another device and so forth, just like roads between towns. So, when the manuals are in another language, I mostly go off pictures, schematics, and diagrams. Then it's just like reading a road map, with the machine components in place of towns, or reading a subway map for different country. It's like you're an electron on a road trip. Just because I didn't go to college doesn't mean that I didn't study. In fact, I think I studied harder. I had to learn all of these important principles by myself and I've never stopped. I study on a daily basis. I've been in business since 1986 and I've studied just about every day of my career. That is another fun part of my job- learning. Will I ever know it all? Heck no! However, I love to learn and the process never stops for me. Because of this, my job is never boring.

There is no substitute for on-the-job training. You can learn certain things in books, and so many things are based on theory, but if someone actually tried to apply these theories without hands-on experience or on-the-job training, it doesn't quite work out. In the beginning of my career, having knowledge of theory definitely would've helped. However, I've had so much hands-on experience over all these years, that my lack of formal education isn't a weakness. Even though it's something that many would consider a disadvantage, I have actually turned it into a strength. My ability to teach myself and learn is the biggest advantage that lets me be successful at my job. Without on-the-job training and hands-on experience, it doesn't take long to be humbled in this business. Even with my experience, I am often wowed by new inventions and innovations that people come up with. The things that young students come up with in science fairs and robotics competitions never cease to amaze me.

My favorite machine is either the last one I built or the one I'm currently working on. They are both winding machines. However, since the machines are all different, I rarely repeat what I'm working on. Another of my favorites is also the biggest machine I've ever worked on. It was a 1948 post-World War II vertical turning lathe (VTL). The machine weighed 65,000 pounds, had a big 6-foot diameter slab of steel that is (on top of the lathe, and) a rotating table. It would take a 3000 pound block of granite that was 2 feet thick and probably 5 feet in diameter and turn it into powder. This machine was owned by a company that made synthetic diamond tools and it used those tools to turn the granite slab into powder. They were testing the wear on the tools by determining how much granite could be turned to powder before for the diamond tools dulled.

In high school, you can actually get hands-on experience. For instance, if you take shop class, you are making things with your hands. If you take computer classes, you're learning the control side of things. If you take electronics or electrical classes, you're learning about wiring and electronic theory. Concentrate on math and science, or talk to your science teacher about going in this direction with lesson or two.

In high school, you can actually get hands-on experience. For instance, if you take shop class, you are making things with your hands. If you take computer classes, you're learning the control side of things. If you take electronics or electrical classes, you're learning about wiring and electronic theory. Concentrate on math and science, or talk to your science teacher about going in this direction with lesson or two.

I may have had some disadvantages growing up in that I wasn't able to pursue a college degree, but I overcame those disadvantages though reading, reading, and more reading. I would advise against my path, though it isn't impossible. I am proof that you don't have to go to college, but it's really the hard way around. There are resources for scholarships for people who can't afford college, and the internet is full of resources to help you begin learning about CNC technology. You can start your career path as soon as you start to read. If you don't have the resources to go to college, it's not a dead-end. A lot of hard work can help you succeed. There are people like Philo T. Farnsworth who designed the picture tube for the first TV. He was a farmer in southern Utah and somehow he came up with the picture tube. Let your imagination go wild. You can do anything if you put your mind to it. If you have obstacles like I did, research and find someone who will help you along with school. Or you can look into programs or grants. I really believe that we are all born with the intelligence to succeed in a career like this. However, what we are not born with is the confidence to have faith in ourselves and trust in ourselves. If you are passionate and have the drive to succeed, you can do anything.

Antenna array - Antenna arrays use electromagnetic wave interference phenomena to enhance a radiative signal in a desired direction and diminish it in the non-desired direction.

Automate - Automation does not require human operators.

Hydraulics - A topic in applied science and engineering dealing with the mechanical properties of liquids.

Lathe - A lathe is a machine tool which rotates a workpiece on its axis to perform various operations such as cutting, sanding, knurling, or drilling with tools that are applied to the workpiece to create an object which has symmetry about an axis of rotation.

Manual - Done by hand, or not using electronics to fulfill a function.

Mill - A machine that uses rotary cutters to remove material from a workpiece advancing in a direction at an angle with the axis of the tool.

Pneumatic - Pneumatics is a section of technology that deals with the study and application of pressurized gas to produce mechanical motion.

(as adapted from Wikipedia.com)

Taylor Barg is a senior mechanical engineering and math major at SMU, a…

Do you have what it takes to be an antarctic engineer? Jim O'Sullivan d…

Who keeps robots running? The Robotics Technicians, that's who! These …