Name Collin Kobayashi

- Education Master's of Business Administration (MBA), B.S. in Manufacturing Design

- Target Audience Elementary School

3D designers like Collin Kobayashi are engineering the future through innovative product development using 3D technology. Read on to learn why being a 3D designer/engineer is such a cool job!

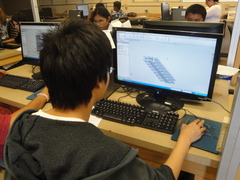

In addition to managing and operating 3D Innovations as President and Principle Consultant, I work to turn 2D sketches into a 3D object through the use of a software program called CAD. CAD stands for Computer-aided Design and is the first step in starting the product development cycle. Most products that are made today are designed through the use of CAD, from your iPhone or iPad to tables and chairs.

In addition to managing and operating 3D Innovations as President and Principle Consultant, I work to turn 2D sketches into a 3D object through the use of a software program called CAD. CAD stands for Computer-aided Design and is the first step in starting the product development cycle. Most products that are made today are designed through the use of CAD, from your iPhone or iPad to tables and chairs.

I also work in an educational capacity to provide 3D CAD and pre-engineering training for middle, high school, and post- secondary education students with the 3D Academy, a division of 3D Innovations.

CAD came out in the late 1980's as a 2D system. My interest in product design started as I was finishing high school in the mid 1990's. At that time the market was changing from 2D to 3D and once I learned what 3D is all about I was hooked. From there I wanted to be involved with the design and manufacturing processes to learn about different industries and how systems are designed to fit with today's technology. I was also interested to see the various engineering aspects of technology products.

When we begin a project for a client, one of the most common things that we get from them is some sort of idea or input that could be in the form of a picture, sketch or in some cases a detailed drawing. Customers come to us because they need to have their idea taken from their 2D format and turned into a 3D model. Once we get the idea plugged into the CAD program we then refine it based on customer needs. Sometimes the clients need the object to look a certain way or function in a certain way and we ensure those aspects are integrated into the 3D model.

One of the methods we use to validate a completed design is 3D printing. 3D printing has been around for 15 or so years now, but it has really come alive in the past 2 or 3 years through more robust technology. 3D printing builds a product in layers based on a CAD design. If you can imagine taking an everyday water bottle that stands about 8 inches high, through 3D printing technology we are able to print it in many paper-thin layers and evaluate if our design will work. One of the greatest benefits of 3D printing is that it allows us to test and evaluate product designs before they go to market.

The best part about the work I do is seeing ideas and concepts that clients bring to us develop into real products that enter the market and become available for consumers to buy. The diversity of projects we work on also keeps things interesting, as no two projects are exactly alike and each project is unique. At 3D Innovations we support military, aerospace, medical devices, locomotive, clean energy solar/wind projects and many other industries. We're based in Hawaii, and locally we have worked on small wind turbine systems and helped a medical device company design and develop a wireless monitoring system. This wireless system we designed for the medical device company allows a laser beam to be placed close to a patient to gather vital signs instead of needing to hook a patient up to numerous wires.

The best part about the work I do is seeing ideas and concepts that clients bring to us develop into real products that enter the market and become available for consumers to buy. The diversity of projects we work on also keeps things interesting, as no two projects are exactly alike and each project is unique. At 3D Innovations we support military, aerospace, medical devices, locomotive, clean energy solar/wind projects and many other industries. We're based in Hawaii, and locally we have worked on small wind turbine systems and helped a medical device company design and develop a wireless monitoring system. This wireless system we designed for the medical device company allows a laser beam to be placed close to a patient to gather vital signs instead of needing to hook a patient up to numerous wires.  We also got to help a company develop a shark deterrent system. This system is an ankle bracelet that you wear into the water and it emits different pulses and signals in the water that help keep the sharks away.

We also got to help a company develop a shark deterrent system. This system is an ankle bracelet that you wear into the water and it emits different pulses and signals in the water that help keep the sharks away.

With 3D Academy I really enjoy seeing students achieve new skills and watching them progress with their projects. Seeing their initial and continuing interest in engineering is really rewarding. I love hearing teachers say that without this type of program/training, their students would have never become involved with STEM and this type of technology.

As a kid, I always liked to play with electronics and computers, but I never really liked science or math. Looking back I realize that what I didn't like about science and math was the fact that these subjects weren't integrated into real-life applications. In class we would study a principle or method of doing something, but then it was never really tied into a real-life scenario. As I got to use CAD and get involved with different aspects of it, I could really see how math and science principles apply. That was sort of the missing link for me. In the career that I chose the science and math principles that I learned in school are a real necessity.

Being involved with the advances in the early stages of this industry was exciting and motivated me to continue down this pathway. Being able to see that designing a product or system was within my realm solidified my decision to further develop my knowledge to enter this industry and career path.

Most of the technical classes that I took in college were challenging because I was never exposed to the areas that my peers had been exposed to for several years. My personal challenge was trying to keep pace with my peers and apply what I was learning to my educational projects, and eventually my daily career activities. Behind all technical activities lies the entrepreneurial aspect of my business. The main challenges are trying to position the business to provide the best possible service while monitoring any changes in the market that might affect our company business model. Keeping up with technology is always challenging as it changes rapidly and systems quickly become obsolete.

Initially, I was not inspired or convinced by anyone to get into the areas of entrepreneurship, engineering/design or manufacturing. Yet, throughout the years of my career, I have met many people and colleagues who have shared their vision of business and technology, which had a profound effect on me. I really believe those experiences positively impacted my decision to remain in the interdisciplinary field that I'm currently in.

With the progression of 3D technology, there are no limits. I see this type of technology expanding to tablet devices and becoming more user-friendly. Other types of 3D technology such as 3D scanning will become more prevalent and provide for an interesting user experience. Processes that are currently manual or semi-automated will soon become fully automated and will require little user input to achieve outputs.

2-D (2-Dimensional): Dimensions are the different planes we experience the world in. The three dimensions we live in are height, width, and depth. When someone refers to something that is 2-D they usually mean it has height and width like a cartoon on your TV. You can measure how high a character stands and how wide he is but you can't measure how deep the scene is.

3D: A three-dimensional medium, display, or performance, especially a cinematic or graphic medium in three dimensions- height, width and depth.

Entrepreneur: a person who organizes and manages any enterprise, especially a business, usually with considerable initiative and risk.

(adapted from wiki.answers.com and www.dictionary.com)

Why did you choose your major? Did you always know this is what you wan…

Lisa Ingham excels on the field and in the classroom as an Engineering …

Why did you choose your major? Did you always know this is what you wan…